Culture of microalgae in hatcheries

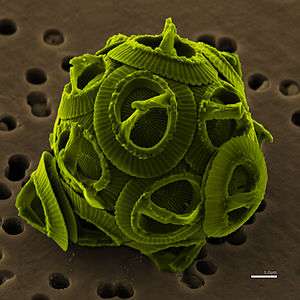

Microalgae or microscopic algae grow in either marine or freshwater systems. They are primary producers in the oceans that convert water and carbon dioxide to biomass and oxygen in the presence of sunlight.[1]

The oldest documented use of microalgae was 2000 years ago, when the Chinese used the cyanobacteria Nostoc as a food source during a famine.[2] Another type of microalgae, the cyanobacteria Arthrospira (Spirulina), was a common food source among populations in Chad and Aztecs in Mexico as far back as the 16th century.[3]

Today cultured microalgae is used as direct feed for humans and land-based farm animals, and as feed for cultured aquatic species such as molluscs and the early larval stages of fish and crustaceans.[4] It is a potential candidate for biofuel production.[5] Microalgae can grow 20 or 30 times faster than traditional food crops, and has no need to compete for arable land.[5][6] Since microalgal production is central to so many commercial applications, there is a need for production techniques which increase productivity and are economically profitable.

Commonly cultivated microalgae species

| Species | Application |

|---|---|

| Chaetoceros sp.[7] | Aquaculture[7] |

| Chlorella vulgaris[8] | Source of natural antioxidants[8] |

| Dunaliella salina[9] | Produce carotenoids (β-carotene)[9] |

| Haematococcus sp.[10] | Produce carotenoids (β-carotene), astaxanthin, canthaxanthin[10] |

| Phaeodactylum tricornutum[8] | Source of antioxidants[8] |

| Porphyridium cruentum[8] | Source of antioxidants[8] |

| Rhodella sp.[7] | Colourant for cosmetics[7] |

| Skeletonema sp[7] | Aquaculture[7] |

| Arthrospira maxima[11] | High protein content – Nutritional supplement[11] |

| Arthrospira platensis[11] | High protein content – Nutritional supplement[11] |

Hatchery production techniques

A range of microalgae species are produced in hatcheries and are used in a variety of ways for commercial purposes. Studies have estimated main factors in the success of a microalgae hatchery system as the dimensions of the container/bioreactor where microalgae is cultured, exposure to light/irradiation and concentration of cells within the reactor.[12]

Open pond system

This method has been employed since the 1950s. There are two main advantages of culturing microalgae using the open pond system.[13] Firstly, an open pond system is easier to build and operate.[13] Secondly, open ponds are cheaper than closed bioreactors because closed bioreactors require a cooling system.[13] However, a downside to using open pond systems is decreased productivity of certain commercially important strains such as Arthrospira sp., where optimal growth is limited by temperature.[12] Although cheaper and easy to build/operate, open pond systems are not widely used because factors such as evaporation, optimal growth temperature and protection from the environment are difficult to maintain.

Air-lift method

This method is used in outdoor cultivation and production of microalgae; where air is moved within a system in order to circulate water where microalgae is growing.[13] The culture is grown in transparent tubes that lie horizontally on the ground and are connected by a network of pipes.[13] Air is passed through the tube such that air escapes from the end that rests inside the reactor that contains the culture and creates an effect like stirring.[13]

Closed reactors

The biggest advantage of culturing microalgae within a closed system provides control over the physical, chemical and biological environment of the culture.[12] This means factors that are difficult to control in open pond systems such as evaporation, temperature gradients and protection from ambient contamination make closed reactors favoured over open systems.[12] Photobioreactos are the primary example of a closed system where abiotic factors can be controlled for. Several closed systems have been tested to date for the purposes of culturing microalgae, few important ones are mentioned below:

Horizontal photobioreactors

This system includes tubes laid on the ground to form a network of loops. Mixing of microalgal suspended culture occurs through a pump that raises the culture vertically at timed intervals into a photobioreactor. Studies have found pulsed mixing at intervals produces better results than the use of continuous mixing. Photobioreactors have also been associated with better production than open pond systems as they can maintain better temperature gradients.[12] An example noted in higher production of Arthrospira sp. used as a dietary supplement was attributed to higher productivity because of a better suited temperature range and an extended cultivation period over summer months.[12]

Vertical systems

These reactors use vertical polyethylene sleeves hung from an iron frame. Glass tubes can also be used alternatively. Microalgae are also cultured in vertical alveolar panels (VAP) that are a type of photobioreactor.[12] This photobioreactor is characterised by low productivity. However, this problem can be overcome by modifying the surface area to volume ratio; where a higher ratio can increase productivity.[12] Mixing and deoxygenation are drawbacks of this system and can be addressed by bubbling air continuously at a mean flow rate. The two main types of vertical photobioreactors are the Flow-through VAP and the Bubble Column VAP.[12]

Flat plate reactors

Flat plate reactors(FPR) are built using narrow panels and are placed horizontally to maximise sunlight input to the system.[14] The concept behind FPR is to increase the surface area to volume ratio such that sunlight is efficiently used.[13][14] This system of microalgae culture was originally thought to be expensive and incapable of circulating the culture.[14] Therefore, FPRs were considered to be unfeasible overall for the commercial production of microalgae. However, an experimental FPR system in the 1980s used circulation within the culture from a gas exchange unit across horizontal panels.[14] This overcomes issues of circulation and provides an advantage of an open gas transfer unit that reduces oxygen build up.[14] Examples of successful use of FPRs can be seen in the production of Nannochloropsis sp. used for its high levels of astaxanthin.[15]

Fermentor-type reactors

Fermentor-type reactors (FTR) are bioreactors where fermentation is carried out. FTRs have not developed hugely in the cultivation of microalgae and pose a disadvantage in the surface area to volume ratio and a decreased efficiency in utilizing sunlight.[13][14] FTR have been developed using a combination of sun and artificial light have led to lowering production costs.[14] However, information available on large scale counterparts to the laboratory-scale systems being developed is very limited.[14] The main advantage is that extrinsic factors i.e. light can be controlled for and productivity can be enhanced so that FTR can become an alternative for products for the pharmaceutical industry.[14]

Commercial applications

Aquaculture

Microalgae is an important source of nutrition and is used widely in the aquaculture of other organisms, either directly or as an added source of basic nutrients.[16] Aquaculture farms rearing larvae of molluscs, echinoderms, crustaceans and fish use microalgae as a source of nutrition.[16] Low bacteria and high microalgal biomass is a crucial food source for shellfish aquaculture.[16]

Microalgae can form the start of a chain of further aquaculture processes. For example, microalgae is an important food source in the aquaculture of brine shrimp. Brine shrimp produce dormant eggs, called cysts, which can be stored for long periods and then hatched on demand to provide a convenient form of live feed for the aquaculture of larval fish and crustaceans.[17][18]

Other applications of microalgae within aquaculture include increasing the aesthetic appeal of finfish bred in captivity.[16] One such example can be noted in the aquaculture of salmon, where microalgae is used to make salmon flesh pinker.[16] This is achieved by the addition of natural pigments containing carotenoids such as astaxanthin produced from the microalgae Haematococcus to the diet of farmed animals.[19]

Biofuel production

In order to meet the demands of fossil fuels, alternate means of fuels are being investigated. Biodiesel and bioethanol are renewable fuels with much potential that are important in current research. However, agriculture based renewable fuels may not be completely sustainable and thus may not be able to replace fossil fuels.[1] Microalgae can be remarkably rich in oils (up to 80% dry weight of biomass) suitable for conversion to fuel.[1] Furthermore, microalgae are more productive than land based agricultural crops and could therefore be more sustainable in the long run.[1] Microalgae for biofuel production is mainly produced using tubular photobioreactors.[1]

Cosmetic and health benefits

The main species of microalgae grown as health foods are Chlorella sp. and Spirulina sp. The main forms of production occur in small scale ponds with artificial mixers.[9] Novel bioactive chemical compounds can be isolated from microalgae like sulphated polysaccharides.[20] These compounds include fucoidans, carrageenans and ulvans that are used for their beneficial properties. These properties are anticoagulants, antioxidants, anticancer agents that are being tested in research.[20] Red microalgae are characterised by pigments called phycobiliproteins that contain natural colourants used in pharmaceuticals and/or cosmetics.[21] Production of long chain omega-3 polyunsaturated fatty acids important for human diet can also be cultured through microalgal hatchery systems.[22]

Biofertilizer

Blue green alga was first used as a means of fixing nitrogen by allowing cyanobacteria to multiply in the soil. Nitrogen fixation is important as a means of allowing inorganic compounds such as nitrogen to be converted to organic forms which can then be used by plants.[23] The use of cyanobacteria is an economically sound and environmentally friendly method of increasing productivity.[24] Rice production in India and Iran have employed this method of using the nitrogen fixing properties of free living cyanobacteria to supplement nitrogen content in soils.[23][24]

Other uses

Microalgae are a source of valuable molecules such as isotopes i.e. chemical variants of an element that contain different neutrons. Microalgae can effectively incorporate isotopes of carbon (13C), nitrogen (15N) and hydrogen (2H) into their biomass.[25] 13C and 15N are used to track the flow of carbon between different trophic levels/food webs.[26] Carbon, nitrogen and sulphur isotopes can also be used to determine disturbances to bottom dwelling communities that are otherwise difficult to study.[26]

Issues

Cell fragility is the biggest issue that limits the productivity from closed photobioreactors.[27] Damage to cells can be attributed to the turbulent flow within the bioreactor which is required to create mixing so light is available to all cells.[27]

See also

References

- 1 2 3 4 5 Yusuf Chisti (2008). "Biodiesel from microalgae beats bioethanol" (PDF). Trends in Biotechnology. 26 (3): 126–131. doi:10.1016/j.tibtech.2007.12.002. PMID 18221809.

- ↑ Pauline Spolaore; Claire Joannis-Cassan; Elie Duran; Arsène Isambert (2006). "Commercial applications of microalgae" (PDF). Journal of Bioscience and Bioengineering. 101 (2): 87–96. doi:10.1263/jbb.101.87. PMID 16569602.

- ↑ Whitton, B., and M. Potts. 2000. The ecology of Cyanobacteria: their diversity in time and space p. 506, Kluwer Academic. ISBN 978-0-7923-4735-4.

- ↑ Barnabé, Gilbert (1994) Aquaculture: biology and ecology of cultured species p. 53, Taylor & Francis. ISBN 978-0-13-482316-4.

- 1 2 Greenwell HC, Laurens LML, Shields RJ, Lovitt RW and Flynn KJ (2010) "Placing microalgae on the biofuels priority list: a review of the technological challenges" J. R. Soc. Interface, 7 (46) 703–726. doi:10.1098/rsif.2009.0322

- ↑ McDill, Stuart (2009-02-10). "Can algae save the world – again?". Reuters. Retrieved 2009-02-10.

- 1 2 3 4 5 6 John Milledge (2011). "Commercial application of microalgae other than as biofuels: a brief review". Reviews in Environmental Science and Biotechnology. 10 (1): 31–41. doi:10.1007/s11157-010-9214-7.

- 1 2 3 4 5 6 Ignacio Rodriguez-Garcia; Jose Luis Guil-Guerrero (2008). "Evaluation of the antioxidant activity of three microalgal species for use as dietary supplements and in the preservation of foods". Food Chemistry. 108 (3): 1023–1026. doi:10.1016/j.foodchem.2007.11.059.

- 1 2 3 Michael A. Borowitzka (1999). "Commercial production of microalgae: ponds, tanks, tubes and fermenters". Journal of Biotechnology. 70 (1–3): 313–321. doi:10.1016/S0168-1656(99)00083-8.

- 1 2 Laurent Dufossé; Patrick Galaup; Anina Yaron; Shoshana Malis Arad; Philippe Blanc; Kotamballi N. Chidambara Murthy; Gokare A. Ravishankar (2005). "Microorganisms and microalgae as sources of pigments for food use: a scientific oddity or an industrial reality?". Trends in Food Science and Technology. 16 (9): 389–406. doi:10.1016/j.tifs.2005.02.006.

- 1 2 3 4 Avigad Vonshak; Luisa Tomaselli (2000). "Arthrospira (Spirulina): systematics and ecophysiology". In Brian A. Whitton; Malcolm Potts. The Ecology of Cyanobacteria: their Diversity in Time and Space. Boston: Kluwer Academic Publishers. pp. 505–522. ISBN 978-0-7923-4735-4.

- 1 2 3 4 5 6 7 8 9 M. Tredici; R. Materassi (1992). "From open ponds to vertical alveolar panels: the Italian experience in the development of reactors for the mass cultivation of phototrophic microorganisms". Journal of Applied Phycology. 4 (3): 221–231. doi:10.1007/BF02161208.

- 1 2 3 4 5 6 7 8 Amos Richmond (1986). Handbook of Microalgal Mass Culture. Florida: CRC Press. ISBN 0-8493-3240-0.

- 1 2 3 4 5 6 7 8 9 Ana P. Carvalho; Luís A. Meireles; F. Xavier Malcata (2006). "Microalgal reactors: a review of enclosed system designs and performances". Biotechnology Progress. 22 (6): 1490–1506. doi:10.1021/bp060065r. PMID 17137294.

- ↑ Amos Richmond; Zhang Cheng-Wu (2001). "Optimization of a flat plate glass reactor for mass production of Nannochloropsis sp. outdoors". Journal of Biotechnology. 85 (3): 259–269. doi:10.1016/S0168-1656(00)00353-9. PMID 11173093.

- 1 2 3 4 5 Arnaud Muller-Feuga (2000). "The role of microalgae in aquaculture: situation and trends" (PDF). Journal of Applied Phycology. 12 (3): 527–534. doi:10.1023/A:1008106304417.

- ↑ Martin Daintith (1996). Rotifers and Artemia for Marine Aquaculture: a Training Guide. University of Tasmania. OCLC 222006176.

- ↑ Odi Zmora; Muki Shpigel (2006). "Intensive mass production of Artemia in a recirculated system". Aquaculture. 255 (1–4): 488–494. doi:10.1016/j.aquaculture.2006.01.018.

- ↑ R. Todd Lorenz; Gerald R. Cysewski (2000). "Commercial potential for Haematococcus microalgae as a natural source of astaxanthin" (PDF). Trends in Biotechnology. 18 (4): 160–167. doi:10.1016/S0167-7799(00)01433-5. PMID 10740262.

- 1 2 Isuru Wijesekara; Ratih Pangestuti; Se-Kwon Kim (2010). "Biological activities and potential health benefits of sulfated polysaccharides derived from marine algae". Carbohydrate Polymers. 84 (1): 14–21. doi:10.1016/j.carbpol.2010.10.062.

- ↑ S. Arad; A. Yaron (1992). "Natural pigments from red microalgae for use in foods and cosmetics". Trends in Food Science & Technology. 3: 92–97. doi:10.1016/0924-2244(92)90145-M.

- ↑ W. Barclay; K. Meager; J. Abril (1994). "Heterotrophic production of long chain omega-3 fatty acids utilizing algae and algae-like microorganisms". Journal of Applied Phycology. 6 (2): 123–129. doi:10.1007/BF02186066.

- 1 2 H. Saadatnia; H. Riahi (2009). "Cyanobacteria from paddy fields in Iran as a biofertilizer in rice plants" (PDF). Plant Soil Environment. 55 (5): 207–212.

- 1 2 Upasana Mishra; Sunil Pabbi (2004). "Cyanobacteria: a potential biofertilizer for rice" (PDF). Resonance. 9 (6): 6–10. doi:10.1007/BF02839213.

- ↑ Richard Radmer; Bruce Parker (1994). "Commercial applications of algae: opportunities and constraints". Journal of Applied Phycology. 6 (2): 93–98. doi:10.1007/BF02186062.

- 1 2 B. J. Peterson (1999). "Stable isotopes as tracers of organic matter input and transfer in benthic food webs: a review". Acta Oecologica. 20 (4): 479–487. Bibcode:1999AcO....20..479P. doi:10.1016/S1146-609X(99)00120-4.

- 1 2 Claude Gudin; Daniel Chaumont (1991). "Cell fragility — the key problem of microalgae mass production in closed photobioreactors". Bioresource Technology. 38 (2–3): 145–151. doi:10.1016/0960-8524(91)90146-B.