Sophorolipid

A sophorolipid is a surface-active glycolipid compound that can be synthesized by a selected number of non-pathogenic yeast species. The first report on sophorolipids was published in 1961,[1] but in the last two decades, because of growing environmental awareness, they have gained increased attention as potential bio-surfactants due to their biodegradability and low eco-toxicity. Today sophorolipids are considered promising bio-surfactants.

Biosurfactants

The term "biosurfactant" can be applied to a surfactant that is obtained directly from a natural source (from plant, animal or microbial cells) by some kind of separation procedure such as extraction, precipitation or distillation. These surfactants have recently gained appeal as an alternative to surfactants organically synthesized from petrochemicals. While many bio-surfactants prove to be acceptable substitutes for their synthetic counterparts, often minor chemical processing can alter their properties to meet specific needs. There is debate regarding how much organic synthesis should be involved while still being able to call a given substance a bio-surfactant, but currently the term is not protected and often "bio-based surfactant" is used interchangeably with "bio-surfactant".

Since surface active agents are abundant in nature, the factor that limits the production of bio-surfactants is definitely not their presence, but likely the technological cost of scaled-up production, separation, and purification. In most instances this makes the cost of bio-based surfactants much higher than the cost of their synthetic equivalents. For example, most biological membranes are made up of a phospholipid bilayer which is composed of surfactant molecules having a polar head and non-polar or hydrophobic tail. However while these phospholipids are ubiquitous in nature, their intracellular location and interaction with other cellular components make their recovery and purification difficult and costly.

Other than sophorolipids, common biosurfactants include rhamnolipids which can be produced by some species of Pseudomonas, and Lecithin which can be obtained either from soybean or from egg yolk and is a common food ingredient. One of interesting surfactants producing by yeast are cellobiose lipids consist of a residue of cellobiose, the disaccharide composed of two glucose residues linked by a 1,4'-beta-glycoside bond, and fatty acid residue as an aglycone .[2] Cellobiose lipids are effective fungicides against many species of ascomycetous and basidiomycetous yeast and mycelial fungi, including human pathogens, Candida albicans and Cryptococcus neoformans [3]

Microbial biosurfactant

Usually the term bio-surfactant is used for the surfactants of microbial origin. This is because the shorter generation time of microbial biomass compared to biomass of animal or plant origin, makes the production of bio-surfactants using bacteria and fungi more industrially relevant.[4] Furthermore, most of the bio-surfactants produced by microbes are synthesized extracellularly and many microbes are known to produce bio-surfactants in large relative quantities. Both these factors (i.e. extracellular location and high concentration) can make the process of recovery, concentration and purification of microbial bio-surfactants simple and cost effective.

Structure and properties

Sophorolipids are glycolipid class of microbial biosurfactants which consist of a hydrophobic fatty acid tail of 16 or 18 carbon atoms and a hydrophilic carbohydrate head, sophorose. which is a glucose di-saccharide with an unusual β-1,2 bond and can be acetylated on the 6′- and/or 6′′- positions. One terminal or sub terminal hydroxylated fatty acid is β-glycosidically linked to the sophorose molecule. The carboxylic end of this fatty acid is either free (acidic or open form) or internally esterified at the 4′′ or in some rare cases at the 6′- or 6′′-position (lactonic form). The hydroxy fatty acid itself counts in general 16 or 18 carbon atoms and can have one or more unsaturated bonds.[6] The physicochemical and biological properties of sophorolipids are significantly influenced by the distribution of the lactone vs. acidic forms produced in the fermentative broth. In general, lactone sophorolipids are more efficient in reducing surface tension and are better antimicrobial agents, whereas acidic sophorolipids display better foaming properties. Acetyl groups can also lower the hydrophilicity of sophorolipids and enhance their antiviral and cytokine stimulating effects.[7]

Biosurfactant properties

Two desirable properties of biosurfactants are biodegradability and low toxicity. While molecules of biological origin are almost always bio-degradable, the rate at which they are degraded can vary significantly as does the degree to which they can be considered toxic. Though many biosurfactants are easily biodegradable and exhibit low toxicity,[8] it is inappropriate to assume that all bio-surfactants possess these same traits under all conditions.[9] Furthermore, even though a bio-surfactant may not be toxic itself, the producing micro-organism could be pathogenic and hence the production of such bio-surfactants may lead to environment concerns. For example, Pseudomonads,including the opportunistic pathogen Pseudomonas aeruginosa, can be used to produce the bio-surfactant rhamnolipid.[10] Similar concerns have been expressed over the widespread production of citric acid by the opportunistic pathogen Aspergillus niger but were limited to ensuring that the final product was sufficiently pure and that the production process was contained. In the case of rhamnolipids, there are many non-pathogenic strains of Pseudomonas which can be used to produce that molecule. Sophorolipids are synthesised by various non pathogenic yeast species such as Candida apicola, Rhodotorula bogoriensis,[11] Wickerhamiella domercqiae,[12] and Starmerella bombicola.[13][14]

Besides biodegradibility, low toxicity, and high production potential, sophorolipids also have a high surface and interfacial activity compared to many chemically synthesized surfactants. These properties help justify the higher costs of production and purification associated with large scale production. Generally a surfactant is considered as a good surfactant if it can lower surface tension (ST) of water from 72 to 30-35 mN/m and the interfacial tension (IT) water/hexadecane from 40 to 1 mN/m. Sophorolipids are reported to reduce ST up to 29 mN/m and IT to 5 mN/m, at the much lower concentrations than the critical micelle concentration(CMC) of many of the synthetic surfactants.[15] In addition to this, sophorolipids are reported to function under wide ranges of temperatures, pressures and ionic strengths; and they also possess a number of other useful biological activities including Antimicrobial,[11] virucidal,[7] Anticancer, Immuno-modulatory properties.[11]

Research

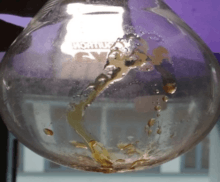

A detailed and comprehensive literature review on the various aspects of sophorolipids production (e.g. producing micro-organisms, bio-synthetic pathway, effect of medium components and other fermentation conditions and downstream process of sophorolipids is available in the published work of Van Bogaert et al.[11][16] This work also discusses potential application of sophorolipids (and their derivatives) as well as the potential for genetic engineering strains to enhance sophorolipid yields. Researchers have focused on optimization of sophorolipid production in submerged fermentation,[17][18] but some efforts have also investigated the possibility of sophorololipid production using solid state fermentation (SSF).[5] The production process can be significantly impacted by the specific properties of the carbon and oil substrates used; and several inexpensive alternatives to more traditional substrates have been investigated. These potential substrates include: biodiesel by-product streams,[19] waste frying oil,[20][21] restaurant waste oil,[22] industrial fatty acid residues,[23] mango seed fat,[24] and soybean dark oil. The use of most of these substrates have resulted in lower yields compared to traditional fermentation substrates.

Limitations

There no doubt that the sophorolipids are the most promising microbial biosurfactant from microbial origin. However even sophorolipids have few shortcomings. For example, sophorolipids are not readily soluble in aqueous medium at acidic pH. Their solubility increases above pH 5.0 and are freely soluble above pH 6.0. However sophorolipids shows instability at pH values higher than 7.0 to 7.5 for long term storage: beyond this point, irreversible hydrolysis of the acetyl groups and ester bonds is observed. Sophorolipids are low foaming surfactants even at high concentrations;[25] these limitations excludes them from a number of applications (for example: preparation of soaps), but makes them suitable for non-foam requiring purposes. (for example: cleansing solution for glass and metallic surfaces, as food additives). Further, even though sophorolipids have excellent antimicrobial, anticancer and antiviral properties, its oral administration is almost impossible, since it gets readily hydrolyzed in stomach as well as intestine, thus they can either be useful for topical preparations such as antimicrobial creams, or may require development of parenteral or novel dosage forms, if to be used for systemic infections.

Chemical modifications of sophorolipids, and polysophorolipids

To enhance the performance of surfactant properties of natural sophorolipids, chemical modification methods have been actively pursued.[26] Recently, researchers demonstrated the possibility of applying sophorolipids as building blocks via ring-opening metathesis polymerization for a new type of polymers, known as polysophorolipids which show promising potentials in biomaterials applications.[27]

References

- ↑ Gorin, P. A. J.; Spencer, J. F. T.; Tulloch, A. P., hydroxyfatty acid glycosides of sophorose from torulopsis magnoliae. Canadian Journal of Chemistry 1961, 39 (4), 846-855.

- ↑ Haskins RH, Thorn JA. Biochemistry of the Ustilaginales. VII. Antibiotic activity of ustilagic acid. Can J Botany 1951: 29: 585–92

- ↑ E Kulakovskaya, T Kulakovskaya Extracellular Glycolipids of Yeasts: Biodiversity, Biochemistry, and Prospects Elsevier AP, 2014

- ↑ Lang, S.; Philp, J. C., Surface-active lipids in rhodococci. Antonie Van Leeuwenhoek 1998, 74 (1-3), 59-70

- 1 2 Parekh, V. J.; Pandit, A. B., Solid State Fermentation (SSF) for the Production of Sophorolipids from Starmerella bombicola NRRL Y-17069 using glucose, wheat bran and oleic acid. Current Trends in Biotechnology and Pharmacy 2012, 6 (4), 418-424.

- ↑ Davila, A.-M.; Marchal, R.; Vandecasteele, J.-P., Sophorose lipid production from lipidic precursors: Predictive evaluation of industrial substrates. Journal of Industrial Microbiology 1994, 13 (4), 249-257.

- 1 2 Shah, V.; Doncel, G. F.; Seyoum, T.; Eaton, K. M.; Zalenskaya, I.; Hagver, R.; Azim, A.; Gross, R., Sophorolipids, microbial glycolipids with anti-human immunodeficiency virus and sperm-immobilizing activities. Antimicrob Agents Chemother 2005, 49 (10), 4093-4100.

- ↑ Deleu, M.; Paquot, M., From renewable vegetables resources to microorganisms: new trends in surfactants. Comptes Rendus Chimie 2004, 7 (6–7), 641-646

- ↑ Mohan, P. K.; Nakhla, G.; Yanful, E. K., Biokinetics of biodegradation of surfactants under aerobic, anoxic and anaerobic conditions. Water Research 2006, 40 (3), 533-540

- ↑ Oliveira, F. J. S.; Vazquez, L.; de Campos, N. P.; de França, F. P., Production of rhamnolipids by a Pseudomonas alcaligenes strain. Process Biochemistry 2009, 44 (4), 383-389

- 1 2 3 4 Van Bogaert, I. N. A.; Zhang, J.; Soetaert, W., Microbial synthesis of sophorolipids. Process Biochemistry 2011, 46 (4), 821-833

- ↑ Chen, J.; Song, X.; Zhang, H.; Qu, Y. B.; Miao, J. Y., Sophorolipid produced from the new yeast strain Wickerhamiella domercqiae induces apoptosis in H7402 human liver cancer cells. Applied Microbiology and Biotechnology 2006, 72 (1), 52-59.

- ↑ Kurtzman, C. P.; Price, N. P.; Ray, K. J.; Kuo, T. M., Production of sophorolipid biosurfactants by multiple strains of the Starmerella (Candida) bombicola yeast clade. FEMS Microbiol Lett 2010, 311 (2), 140-146.

- ↑ Parekh, V. J.; Pandit, A. B., Optimization of fermentative production of sophorolipid biosurfactant by starmerella bombicola NRRL Y-17069 using response surface methodology. International Journal of Pharmacy and Biological Sciences 2011, 1 (3), 103-116

- ↑ Cooper, D. G.; Paddock, D. A., Production of a Biosurfactant from Torulopsis bombicola. Appl Environ Microbiol 1984, 47 (1), 173-176.

- ↑ Van Bogaert I (2008) Microbial synthesis of sophorolipids by the yeast Candida bombicola. PhD-thesis, Faculty of Bioscience Engineering, Ghent University, Ghent, Belgium, 239 p

- ↑ Parekh, V. J.; Pandit, A. B., Optimization of fermentative production of sophorolipid biosurfactant by starmerella bombicola NRRL Y-17069 using response surface methodology. International Journal of Pharmacy and Biological Sciences 2011, 1 (3), 103-116.

- ↑ Rispoli, F. J.; Badia, D.; Shah, V., Optimization of the fermentation media for sophorolipid production from Candida bombicola ATCC 22214 using a simplex centroid design. Biotechnology Progress 2010, 26 (4), 938-944.

- ↑ Ashby, R.; Nuñez, A.; Solaiman, D. Y.; Foglia, T., Sophorolipid biosynthesis from a biodiesel co-product stream. Journal of the American Oil Chemists' Society 2005, 82 (9), 625-630.

- ↑ Fleurackers, S. J. J., On the use of waste frying oil in the synthesis of sophorolipids. European Journal of Lipid Science and Technology 2006, 108 (1), 5-12.

- ↑ Wadekar, S.; Kale, S.; Lali, A.; Bhowmick, D.; Pratap, A., Sophorolipid production by starmerella bombicola (ATCC 22214) from virgin and waste frying oils, and the effects of activated earth treatment of the waste oils. JAOCS, Journal of the American Oil Chemists' Society 2012, 89 (6), 1029-1039.

- ↑ Shah, V.; Jurjevic, M.; Badia, D., Utilization of restaurant waste oil as a precursor for sophorolipid production. Biotechnol Prog 2007, 23 (2), 512-515.

- ↑ Ashby, R. D.; Solaiman, D. K.; Foglia, T. A., The use of fatty acid esters to enhance free acid sophorolipid synthesis. Biotechnol Lett 2006, 28 (4), 253-260.

- ↑ Parekh, V. J.; Patravale, V. B.; Pandit, A. B., Mango kernel fat: A novel lipid source for the fermentative production of sophorolipid biosurfactant using Starmerella Bombicola NRRL-Y 17069. Annals of Biological Research 2012, 3 (4), 1798-1803.

- ↑ Hirata, Y.; Ryu, M.; Oda, Y.; Igarashi, K.; Nagatsuka, A.; Furuta, T.; Sugiura, M., Novel characteristics of sophorolipids, yeast glycolipid biosurfactants, as biodegradable low-foaming surfactants. J Biosci Bioeng 2009, 108 (2), 142-146.

- ↑ http://www.prnewswire.com/news-releases/dsm-enters-into-agreement-with-synthezyme-llc-for-production-of-surfactants-243539671.html

- ↑ Peng, Yifeng; Munoz-Pinto, Dany J.; Chen, Mingtao; Decatur, John; Hahn, Mariah; Gross, Richard A. (10 November 2014). "Poly(sophorolipid) Structural Variation: Effects on Biomaterial Physical and Biological Properties". Biomacromolecules. 15 (11): 4214–4227. doi:10.1021/bm501255j.