Fremont Assembly

| Industry | Automotive industry |

|---|---|

| Predecessor | Oakland Assembly 1916–c. 1965 |

| Successor |

NUMMI 1984–2010 Tesla Factory (2010–present) |

| Founded | 1962 |

| Headquarters |

Fremont, California, United States 37°29′41.12″N 121°56′41.16″W / 37.4947556°N 121.9447667°WCoordinates: 37°29′41.12″N 121°56′41.16″W / 37.4947556°N 121.9447667°W |

| Products | cars and trucks |

Production output | 1,072 vehicles daily |

| Services | Automotive manufacturing |

| Owner | General Motors |

| Parent | General Motors |

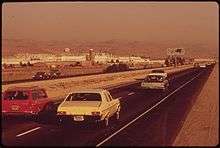

Fremont Assembly was a General Motors automobile factory in Fremont, California. Groundbreaking for the plant occurred in September 1961.[1] It was the new site for production in the San Francisco area in 1962 when production moved from the older Oakland Assembly. Production continued through March 1 of 1982 when the plant was closed after production problems. Partially demolished (south end and water tower), the remaining plant was refurbished as the more successful NUMMI joint-venture with Toyota in 1984[2] and later became the Tesla Factory, Tesla Motors' automobile plant in 2010.

Production

The 411-acre (166 ha) Fremont plant produced GM A platform Chevrolet, Pontiac, Buick, and Oldsmobile cars, as well as GMC trucks for the Western United States.[3]

Statistics

- Hourly output: 42 cars and 25 trucks per hour (two shifts daily)

- Daily total: 1,072 vehicles

- Lines: 112 body styles (44 cars and 68 trucks)

Models

Some of the models produced at the plant included:

- 1962–81 GMC C/K

- 1963–77 Chevrolet Chevelle

- 1963–77 Pontiac LeMans

- 1963–81 Chevrolet El Camino

- 1964–73 Pontiac GTO

- 1964–80 Oldsmobile Cutlass, 442

- 1971–77 GMC Sprint

- 1973–77 Buick Century

- 1973–81 Buick Regal

- 1978–81 GMC Caballero

- 1982 Chevrolet Celebrity

- 1982 Oldsmobile Cutlass Ciera

Buick-Oldsmobile-Pontiac Assembly Division (1945–65)

Plants operating under Chevrolet Assembly management prior to General Motors Assembly Division management (most established pre-1945) were located at St. Louis, Missouri; Janesville, Wisconsin; Buffalo, New York; Norwood, Ohio; Flint (#2), Michigan; Oakland, California; Tarrytown, New York; Lakewood, Georgia; Leeds, Missouri; Baltimore, Maryland; Los Angeles (Van Nuys), California; Ypsilanti (Willow Run), Michigan; and Lordstown, Ohio. Framingham, Massachusetts is unusual in that it changed from B-O-P to Chevy management prior to becoming GMAD.

The terminology is confusing because most plants assembled more than just Chevrolet or B-O-P, and refers to the management structure only. The five brands originated vehicles from their respective "home" plants, where vehicles were assembled locally for their respective regions. Vehicles were also produced in "knock-down" kits and sent to the branch assembly locations. The "home" branches were Flint, Michigan for both Buick and Chevrolet; Oldsmobile at Lansing, Michigan; Pontiac at Pontiac, Michigan; and Cadillac at Detroit, Michigan.[4]

- Arlington Assembly, Arlington, Texas

- Doraville Assembly, Atlanta, Georgia

- Fairfax Assembly, Kansas City, Kansas

- Framingham Assembly, Framingham, Massachusetts

- Fremont Assembly, Fremont, California

- Linden Assembly, Linden, New Jersey

- South Gate Assembly, South Gate, California

- Wilmington Assembly, Wilmington, Delaware

See also

References

- ↑ "Earth Turned for GM Plant". The Argus (Fremont, CA. 20 Sep 1961. p. 1. Retrieved 15 May 2015.

- ↑ Glass, Ira (July 17, 2015). "NUMMI 2015, Transcript". Archived from the original on June 19, 2016. Retrieved November 9, 2016.

nobody in the GM plant would ever ask to help. They would come and yell at you because you got behind. I can't remember any time in my working life where anybody asked for my ideas to solve the problem. There's nobody to pull you out at General Motors, so you're going to let something go. Hundreds of misassembled cars. Never stop the line. . One reason car execs were in denial was Detroit's insular culture. Yes, unions and management were always at each other's throats, and yes, GM and its suppliers had a destructive relationship that seemed to almost discourage quality. But everyone had settled into comfortable roles in this dysfunctional system and learned to live with it. -it took about a decade and a half after NUMMI for change to even begin to take hold at GM. By the year 2000, GM finally started to see a generational transformation.

- ↑ "fremont-tour". ultra-high-compression.com. Retrieved 2015-05-15.

- ↑ http://vcca.org/forum/ubbthreads.php/topics/99892/Re_Fisher_Body_Company