Digital radiography

Digital radiography is a form of X-ray imaging, where digital X-ray sensors are used instead of traditional photographic film. Advantages include time efficiency through bypassing chemical processing and the ability to digitally transfer and enhance images. Also, less radiation can be used to produce an image of similar contrast to conventional radiography.

Instead of X-ray film, digital radiography uses a digital image capture device. This gives advantages of immediate image preview and availability; elimination of costly film processing steps; a wider dynamic range, which makes it more forgiving for over- and under-exposure; as well as the ability to apply special image processing techniques that enhance overall display quality of the image.

Detectors

There are two major variants of digital image capture devices: flat panel detectors (FPDs) and high-density line-scan solid state detectors. (Baes, 2015)

Flat Panel Detectors

FPDs are further classified in two main categories:

1. Indirect FPDs Amorphous silicon (a-Si) is the most common material of commercial FPDs. Combining a-Si detectors with a scintillator in the detector’s outer layer, which is made from caesium iodide (CsI) or gadolinium oxysulfide (Gd2O2S), converts X-rays to light. Because of this conversion the a-Si detector is considered an indirect imaging device. The light is channeled through the a-Si photodiode layer where it is converted to a digital output signal. The digital signal is then read out by thin film transistors (TFTs) or fiber-coupled CCDs. The image data file is sent to a computer for display.

2. Direct FPDs. Amorphous selenium (a-Se) FPDs are known as “direct” detectors because X-ray photons are converted directly into charge. The outer layer of the flat panel in this design is typically a high-voltage bias electrode. X-ray photons create electron-hole pairs in a-Se, and the transit of these electrons and holes depends on the potential of the bias voltage charge. As the holes are replaced with electrons, the resultant charge pattern in the selenium layer is read out by a TFT array, active matrix array, electrometer probes or microplasma line addressing.

High-density Line-scan Detectors

A high-density line-scan solid state detector is composed of a photostimulable barium fluorobromide doped with europium (BaFBr:Eu) or caesium bromide (CsBr) phosphor. The phosphor detector records the X-ray energy during exposure and is scanned by a laser diode to excite the stored energy which is released and read out by a digital image capture array of a CCD.

Radiological examinations

Medical

Digital Radiography

(This is an expanding and changing field of science, and subject to revision)

Digital Radiography is replacement of the former Analog methods of detection, with the almost instantaneous development of images on a digital display, instead of the former methods of film and the associated delay in time and chemistry consumption.

At present there are two distinct methods of Digital Radiography.

Computed radiography (CR); This resembles the old analogue system of a light sensitive film sandwiched between two x-ray sensitive screens, the difference being the analogue film has been replaced by an imaging plate, which records the image to be read by an image reading device, which transfers the image usually to a Picture archiving and communication system (PACS)

Direct radiography (confusingly also abbreviated to DR). A direct radiography system has a sealed imaging cassette, this contains an imaging system not entirely unlike the CCD in a digital camera. the image is recorded then transmitted wirelessly direct to the PACS (hence the name Direct Radiography)

CR vs DR

Initially CR was the system of choice; early DR systems were prohibitively expensive (each cassette costs £40-£50K), and as the 'technology was being taken to the patient', prone to damage.

Therefore, CR system were initially cheaper, less likely to critical failure, and more akin to previous analogue systems...but as newer DR systems have been developed the cassettes have become cheaper more durable and now incorporate wireless technology. Also manufacturers of the x-ray equipment are now producing integrated DR x-ray systems. These integrated systems cost no more than the x-ray equipment alone, and often include warranties for replacement of the DR cassettes. As a result, the CR is becoming the 'old' technology, and as x-ray equipment is replaced the DR systems are proving faster, more efficient and producing higher quality radiographs

Dental

The radiological examinations in dentistry may be classified into intraoral – where the film or sensor is placed in the mouth, the purpose being to focus on a small region of the oral-maxillofacial region and extraoral where the film or sensor is placed outside the mouth aiming to visualize the entire oral maxillofacial region. Extraoral imaging is further divided into orthopantomogram, showing a section, curved following more or less mandible shape, of the whole maxillofacial block and cephalometric analysis showing a projection, as parallel as possible, of the whole skull.

Digital radiography provides an opportunity to further reduce the radiation dose by 40 to 60 percent.[1] In addition, it provides the dental clinician with the ability to store their images on a computer. This provides two key advantages over film in the form of full screen images that can be enhanced and zoomed in on, aiding diagnostics and providing easier patient communication, as well as allowing dental offices to communicate images electronically, allowing for simpler referrals and, where applicable, easier insurance claim submission.

Industrial Usage of X-Rays

Aerospace

Aerospace is an industry that has experienced great growth in recent decades. Non Destructive Testing (NDT) in aerospace has a special driver of its own due to the high levels of human traffic involved; the crash of a civil or military airliner has the ability to cause loss of life reaching catastrophic proportions. Therefore, strict NDT specifications have been set to detect very small cracks and defects in engine turbo discs, blades and airframe structures, in both production and ongoing maintenance.

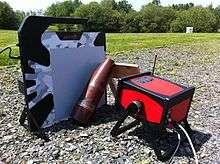

Security

Digital Radiography (DR) has existed in various forms (for example, CCD and amorphous Silicon imagers) in the security X-ray inspection field for over 20 years and is rapidly replacing the use of film for inspection X-rays in the Security and NDT fields. DR has opened a window of opportunity for the security NDT industry due to several key advantages including excellent image quality, high POD, portability, environmental friendliness and immediate imaging.[2]

Digital radiographic systems

Digital dental radiography comes in two forms: direct, that connect directly to the computer via USB and provides immediate images, and indirect (photostimulable phosphor plates, or PSP) which uses plates that are radiated and then digitally scanned.

Direct digital sensors represent a significant initial investment, but in addition to the convenience of digital images, provide instant images that can reduce the time the patient spends in the dental chair. They also reduce the need for the constant purchase of film and the necessary development chemicals. Early systems used CCD sensor technology, but changed to Amorphous Silicon (aSi:H) sensors following their introduction in early 1998-9.

Indirect digital imaging (also termed Computed Radiography) utilizes a reusable plate in place of the film. After X-ray exposure the plate (sheet) is placed in a special scanner where the latent formed image is retrieved point by point and digitized, using laser light scanning. The digitized images are stored and displayed on the computer screen. This method is halfway between old film-based technology and current direct digital imaging technology. It is similar to the film process because it involves the same image support handling but differs in that the chemical development process is replaced by scanning. This is not much faster than film processing and the resolution and sensitivity performances are contested. PSP has been described as having an advantage of fitting within any pre-existing equipment without modification because it replaces the existing film; however, it includes extra costs for the scanner and replacement of scratched plates.

Invention

In the early 1960s, while developing compact, lightweight, portable equipment for the onboard nondestructive testing (NDT) of naval aircraft, Frederick G. Weighart[3][4] and James F. McNulty (U.S. radio engineer)[5] at Automation Industries, Inc., then, in El Segundo, California co-invented the apparatus, which produced the world’s first image to be digitally generated with x-rays. Square wave signals were detected on the fluorescent screen of a fluoroscope to create the image.

Historical milestones for digital intraoral sensors

- 1987 – RVG (radiovisiography), Trophy Radiology (France) introduced the world's first intraoral X-rays imaging sensor. Trophy Radiology patented it under the restricted name radiovisiography (other companies use the phrase digital radiography) and continues to produce intraoral sensors today under the Carestream Dental name, which is used under license by Carestream Health. Carestream Dental has released a wireless version of their RVG intraoral sensor named the RVG 6500.

- 1992 – Sens-a-Ray of Regam Medical System AB (Sundsvall, Sweden) is introduced. The company went out of business and their technology was purchased by Dent-X, recently renamed to ImageWorks (USA). First distributor in North America was Video Dental Concepts 1992

- 1993 – VisualX of Gendex-Italy (subsidiary of USA company).

- 1994 – CDR of Schick Technologies, USA. Schick were the first company to offer three film-like sizes of sensor, as well providing the significant breakthroughs of CMOS-APS technology (1998), USB connectivity (1999), the first sensors without cables (2003) and the first sensors with replaceable cables (2008). They launched their second generation of CMOS-APS chips in 2009. Schick merged with Sirona (Germany) in 2006 and is now part of Sirona Dental Systems, LLC.

- 1995 – SIDEXIS of Sirona, DEXIS of ProVison Dental Systems, Inc. (renamed DEXIS, LLC following its acquisition by Danaher Corp.), DIGORA (PSP solution) of Soredex (Finland)

- 2011 - Sodium Dental (Sodium Systems llc) were the first to offer digital intraoral x-ray sensor repair to dental practitioners and dental equipment companies.

Today there are many other products available under a lot of different names (rebranding is quite usual for this type of product).

Historical milestones for digital panoramic systems

- 1995 – DXIS, the first dental digital panoramic X-rays system available on the market, created by Catalin Stoichita at Signet (France). DXIS targeted to retrofit all the panoramic models.

- 1997 – SIDEXIS, of Siemens (currently Sirona, Germany) offered for Ortophos Plus panoramic unit, DigiPan of Trophy Radiology (France) offered for the OP100 panoramic made by Instrumentarium (Finland).

- 1998–2004 – many panoramic manufacturers offered their own digital system.

- 2005 – SCAN300FP, of 'Ajat' (Finland) is the latest innovation offered. It shows the feature to acquire many hundreds of mega bytes of image information at high frame rate and to reconstruct the panoramic layer by intensive post acquisition computing like a computed tomography. The main advantage is the ability to reconstruct focused differently. The drawback is the low signal/noise ratio of primary information which involves much software work for correction. Also the ability to reconstruct various layers raises the importance of the geometrical distortions already high in dental panoramic radiography. Since 2008 the SCAN300FP system is available in Ajat ART PLUS and ART PLUS C system.

See also

External links

| Library resources about Digital radiography |

- ↑ "DENTAL RADIOGRAPHIC EXAMINATIONS: RECOMMENDATIONS FOR PATIENT SELECTION AND LIMITING RADIATION EXPOSURE" (PDF). FDA. ADA. 2012.

- ↑ "http://www.vidisco.com/node/273". Digigital Radiography. Vidisco. Retrieved 2012-09-27. External link in

|title=(help) - ↑ U.S. Patent 3,277,302, titled “X-Ray Apparatus Having Means for Supplying An Alternating Square Wave Voltage to the X-Ray Tube”, granted to Weighart on October 4, 1964, showing its patent application date as May 10, 1963 and at lines 1-6 of its column 4, also, noting James F. McNulty’s earlier filed co-pending application for an essential component of invention

- ↑ U.S. Patent 3,482,093, see also this patent, titled "Flouroscopy", referencing US Patent 3277302 to Weighart and detailing the flouroscopy procedure used for nondestructing testing.

- ↑ U.S. Patent 3,289,000, titled “Means for Separately Controlling the Filament Current and Voltage on a X-Ray Tube”, granted to McNulty on November 29, 1966 and showing its patent application date as March 5, 1963