Bacton Gas Terminal

| Bacton Gas Terminal | |

|---|---|

Bacton Gas Terminal, from the west in 2007 | |

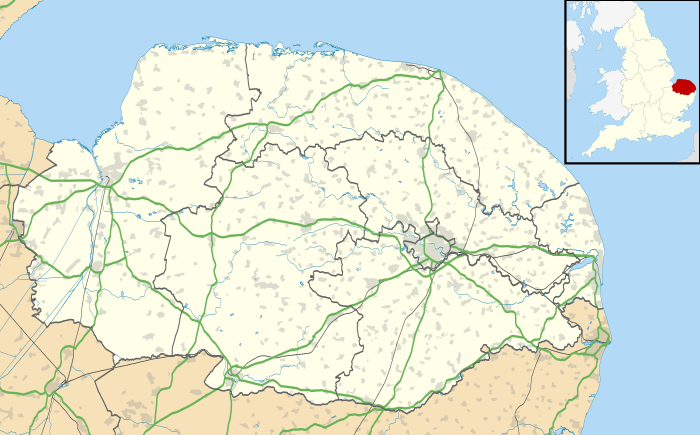

Location within Norfolk | |

| General information | |

| Type | Gas terminal |

| Location | Bacton, NR12 0JE |

| Coordinates | 52°51′39″N 1°27′27″E / 52.8608°N 1.4575°ECoordinates: 52°51′39″N 1°27′27″E / 52.8608°N 1.4575°E |

| Current tenants | Eni, National Grid, Shell UK, Perenco |

| Construction started | 13 August 1968 |

| Completed | 1968 |

| Cost | £10 million (Shell 1968), £5 million (Phillips 1969) |

| Height | 410-470ft (three radio masts) |

| Technical details | |

| Floor area | 200 acres (0.81 km2) |

The Bacton Gas Terminal is a complex of six gas terminals within four sites located on the North Sea coast in North Norfolk near Paston and between Bacton and Mundesley. The nearest main town is North Walsham. The other main UK gas terminals which receive gas from the UK continental shelf are at St Fergus, Aberdeenshire; Easington, East Riding of Yorkshire; Theddlethorpe, Lincolnshire; CATS Terminal, Teesside; and Rampside gas terminal, Barrow, Cumbria.

History

The Bacton complex which covers an area of about 180 acres (73 ha) opened during 1968. It has a frontage of 1 km (3200 feet) along the cliff top. It was initially built by Shell-Esso, Phillips Petroleum-Arpet Group, Amoco-Gas Council. Planning permission had been given on 16 June 1967 by Anthony Greenwood, Baron Greenwood of Rossendale. The Leman field began production on 13 August 1968 (joint Shell-Esso and joint Amoco-Gas Council), the Hewett field (Phillips Petroleum-Arpet Group) began operations in July 1969 and the Indefatigable field (joint Shell-Esso and joint Amoco-Gas Council) began production in October 1971. Construction of the £5 million Phillips-Arpet plant began in April 1968. Gas from the Shell-Esso part of the Leman field was delivered to Bacton via a 34-mile-long pipeline. A 36-inch diameter 140-mile-long pipeline (Number 2 feeder main) costing £17 million was built by Italsider from Bacton to the National Transmission System near Rugby. When completed in 1968 the terminal had a total gas throughput capacity of 3,955 MMSCFD (112 million m3 a day).[1] The Gas Council marketed the new North Sea gas as High Speed Gas.

Operation

The Bacton complex consists of six gas terminals. The terminals are:

- Shell

- Eni

- Perenco

- National Grid - feeding the National Transmission System (NTS)

- Interconnector UK (within the National Grid site)

- BBL (Bacton-Balgzand line) (within the Shell site)

Three of the terminals (Eni, Perenco and Shell) receive gas from Southern North Sea (SNS) offshore gas fields. Initial gas processing, such as removal of free water, takes place on the offshore gas installations. At the terminals gas and condensate are received in a slugcatcher (to separate gas and hydrocarbon liquids and condensed water), the gas is compressed if necessary, dehydrated using triethylene glycol, and chilled to achieve a specified hydrocarbon dewpoint. Sour gas (sulphurous) had previously been removed at the Eni site by amine gas treating, now decommissioned. Hydrocarbon condensate is stabilized and piped by the British Pipeline Agency along the route of the former North Walsham to Mundesley railway line to the North Walsham rail terminal and thence by rail to an oil refinery at Harwich Essex. Treated gas from the three terminals flows to the National Grid terminal located immediately to the south of the three reception terminals. Two of the terminals (Interconnector and BBL) receive gas from, or deliver gas to, the gas networks of continental Europe. Manifolds within the National Grid terminal blend the gas and distribute it to the National Transmission System at around 1000 psig (69 bar).

The offshore reception terminals were originally run by Royal Dutch Shell-Esso, Phillips Petroleum-Arpet Group and Amoco-Gas Council. Amoco and BP announced they had merged in 1998 to form BP Amoco, the merged organisation changed its name to BP in 2001. Perenco took over the BP operations in September 2003. Tullow had begun operations in 2003 taking over the Phillips Petroleum terminal operations, ENI took over the Tullow Oil operations in December 2008.

Shell terminal

The Shell terminal, the most easterly of the three, receives gas and condensate from three offshore pipelines. These are a 55.7 km long 30-inch pipeline from the Leman 49/26AP offshore installation; a 106 km long 30-inch pipeline from the Sean PP installation; and a 73 km 24-inch pipeline from the Clipper PT installation. A mothballed 30-inch pipeline formally delivered gas from the Leman 49/26BT installation to Bacton. The terminal also receives gas from the 474 kilometres (295 mi) long 34-inch SEAL Pipeline, which transports gas from the Shearwater and Elgin-Franklin gas fields in the Central North Sea. The SEAL Pipeline is the longest on the UK Continental Shelf. The Shell plant has a gas treatment capacity of 900 MMSCFD (million standard cubic feet per day) and a condensate stabilization capacity of 8,000 barrels per day (1,270 m3/day). The gas hydrocarbon dewpoint is achieved by propane refrigeration. Truck loading facilities for condensate were originally provided.[2] It employs 46 people and began operations in 1968. The BBL Pipeline terminal became operational in December 2006 and is located within the Shell terminal. The BBL terminal is operated, but not owned, by Shell.

Eni terminal

The most westerly of the terminals is owned by Eni of Italy. It receives gas from two 30-inch pipelines from the Hewett field (27.7 km and 32.8 km long) and a 62 km long 20-inch pipeline from Lancelot 48/17A offshore installation (LAPS complex). A decommissioned 24-inch pipeline formerly delivered gas from the Thames 49/28A offshore installation. Gas and liquid from each pipeline are received and processed separately.[3] After gas and condensate are separated in vessel-type slugcatchers and filter-separators each gas stream is fiscally metered (for tax purposes). The two Hewett field gas streams are combined and increased in pressure through an eductor. The gas stream was formerly treated with amine to remove sulphur compounds, this facility was decommissioned in 2000 when production from the sour Hewett Upper Bunter reservoir was shut-in. The gas is comingled with the LAPS gas then compressed. It was formerly dehydrated using triethylene glycol and underwent hydrocarbon dew point reduction by chilling with propane. Finally it was fiscally metered (for sales) and transferred to the Bacton NTS plant. Formerly the terminal had pentane storage tanks and a truck loading facility.[2] The terminal has two GE 11MW Frame 3 and one GE 3.7MW Frame 1 gas turbines, connected to three centrifugal compressors. In 2011 the Eni Terminal was split by segregating the reception and some of the compression facilities from the dehydration and dewpoint control plant, the latter was decommissioned. Now after compression the gas is sent to the Perenco site for dehydration and dewpoint control. The separated condensate is also sent to the Perenco site. During late 2013/2014 the redundant processing facilities were removed and now the majority of the Eni site is unused.

Perenco terminal

This terminal, located between the Shell terminal and the Eni terminal, processes gas from pipelines from the Leman, Indefatigable and Trent & Tyne fields. These include two 30-inch pipelines from the Leman 49/27AP and Leman 49/27B offshore installations (61.82 km and 64.9 km respectvely) and a 24-inch pipeline from the Trent 43/24 offshore installation. The processing plant comprises two parallel trains (A1 plant and A2 plant) each with an initial processing capacity of 1,000 MMSCFD (2.8 million m3/day) and a condensate stabilization capacity of 600 m3/day, stabilized condensate is stored in gasoline storage tanks[2] prior being piped to the North Walsham rail terminal. Gas from the 'Leman' pipe-type slugcatcher is normally routed to dewpoint control plant streams 1, 2 and 3; gas from the 'Inde' pipe-type slugcatcher is routed to dewpoint control plant streams 4 & 5. Gas from the Tyne and Trent pipe-type slugcather can be routed to either dew point control plant. There is also a cross-connection to and from the Shell terminal.

The ENI terminal was integrated into the Perenco Terminal in 2011, thereby diverting the Hewett, LAPS and at one time Thames gas and condensate from the slug catchers and compression in the Eni terminal to the Perenco terminal upstream of the dehydration and dew point control plant.

National Grid - The National Transmission System (NTS)

Connections from the offshore terminals comprise two 30-inch lines from the Eni terminal (now disused), two 30-inch lines from the Perenco terminal, four 24-inch lines from the Shell terminal and a 36-inch line from the BBL pipeline. Gas from the Perenco and Shell terminals is filtered, measured through orifice plates and the flow regulated by volume into a manifold system.[2] Facilities for heating the gas by pressurised hot water are provided should this be necessary if the pressure of the incoming gas has to be reduced appreciably. There are four 36-inch manifolds within the National Grid terminal, plus one spare, which can receive flow from any of the incoming lines, thus blending the gas.[2] A 24-inch by-pass ringmain around the site perimeter enables the terminal to be completely by-passed in an emergency. The blended gases are odourised (1 kg odorant for 60,000 m3 of gas)[4] and the flow rate is measured and distributed then to the National Transmission System via five outgoing feeders:

- Feeder No 2 to Brisley, Peterborough and Rugby, 36-inch

- Feeder No 3 to Roudham Heath, Cambridge and Hitchin, 36-inch

- Feeder No 4 to Great Ryburgh, Kings Lynn and Alrewas, 36-inch

- Feeder No 5 to Yelverton, Diss, Chelmsford and Horndon-on-the-Hill, 36-inch

- Feeder No 27 to Kings Lynn, 36-inch

From the National Grid terminal gas can also be sent to, or received from, Zebrugge, Belgium via the Interconnector, received from the Netherlands via the 36-inch Balgzand Bacton Line BBL Pipeline. Gas is also sent via the 12-inch BPA pipeline to Great Yarmouth power station, and distributed to the local area via a low pressure gas distribution system.

Interconnector UK terminal

The Interconnector terminal is located within the National Grid terminal. It can import gas from, or export gas to, Zebrugge, Belgium via a 235 km pipeline operating at up to 147 bar. There is a 30-inch direct access line from the SEAL pipeline. It works via four GE LM2500 gas turbines and a Thermodyn centrifugal compressor in its compressor station, which was built by Kværner John Brown (now called Aker Solutions). The Interconnector was commissioned in 1998.

BBL terminal

The BBL (Bacton-Balgzand line) terminal is located within the Shell terminal, it receives gas from the compressor station in Anna Paulowna in the Netherlands. The Bacton reception plant is owned by BBL Company and the plant is operated by Shell.[5] Gas arrives at Bacton at approximately seabed temperature and a pressure of up to 135 bar but which varies depending on the amount of line pack. Bacton’s role is to reduce the pressure for entry to the National Transmission System. As such, significant Joule-Thomson cooling may occur prior to gas injection into the NTS. Therefore four identical parallel streams are installed at Bacton, each equipped with a direct-fired water bath heater on a slipstream and designed to operate as three duty and one standby at maximum flow conditions, in order to control the delivery temperature and pressure of the gas. The BBL pipeline is 235 km long and was commissioned in December 2006.

Shell gas fields

Indefatigable and Indefatigable SW

The Indefatigable field is 60 miles (100 km) north-east of Great Yarmouth. It is a Rotliegendes sandstone reservoir 200-300 ft (60-90 m) thick at a depth of 8,000-9,000 ft (2440-2740 m).[6] It is licensed to Shell (Blocks 49/24 and 49/19) and Perenco (Blocks 49/23 and 49/18). The field was discovered in June 1966 and production started in September 1971. It had initial recoverable reserves of 125 billion m3.[7] The Inde 49/24J (JD & JP) installation started in September 1971, Inde 49/24K started in March 1973, Inde 49/24L started in October 1978 and the Inde 49/24M platform started in October 1985. Gas production was via the Amoco (now Perenco) Inde 49/23A installation, then via a joint line to the Leman 49/27B installation and thence to Bacton. The Inde 49/24 field ceased production on 5 July 2005. The Juliet, Kilo, Lima, Mike and November were removed by July 2011.[8] Indefatigable SW was discovered in June 1967 and production started in October 1989.[9] It is named after HMS Indefatigable World War I Royal Navy battlecruiser.

Leman

The Leman field is 30 miles (48 km) north-east of Great Yarmouth. It is 800 ft (240 m) thick Rotliegendes sandstone reservoir at a depth of about 6,000 ft (1830 m). It is about 18 miles (29 km) long by 5 miles (8 km) wide.[6] It was discovered in August 1966 is licensed to Shell (Block 49/26) and Perenco (Block 49/27). The Leman 49/26A (AD1, AD2, AP & AK) installation began production in August 1968. It had initial recoverable reserves of 292 billion m3.[7] It is connected to the Shell terminal at Bacton. Leman 49/26B (BT & BH) and 49/26B (BP & BD) began production in November 1970. Leman 49/26C (CD & CP) began in February 1972. Leman 49/26D began in August 1974. Leman 49/26E started in August 1983. Leman 49/26F and 49/26G began in September 1987. The Leman complex of platforms connects to Bacton via Leman 49/26A, and is directly east of the Hewett complex. A decommissioned 36-inch pipeline formerly delivered gas from Leman 49/26BT to Bacton. The field is named after the Leman Sandbank upon which it is situated.[10] Field gas is piped to Bacton via Leman 49/26A Complex (AK, AP, AD1 and AD2) where facilities consist of two RB211 (driving HP compression) and two Avon (driving LP compression) gas turbines.

In the mid-1990s the glycol dehydration facilities of several installations in the Inde and Leman fields was decommissioned. This enabled the installations to become normally unattended installations (NUIs) reducing manning costs and the risks to personnel.

Corvette

Corvette 49/24A connects via a 20-inch pipeline to the Leman 49/26A complex. Run by Shell and owned equally by Shell and Esso. Discovered in January 1996 and production started in January 1999. It is named after the corvette ship.

Brigantine

This connects via the Leman platforms. It is owned by Shell and Esso and run by Shell. Brigantine A began was discovered in 1986; B was discovered in 1997; and C was discovered in 1998. All three fields began production in October 2001 via the 49/19BR and 49/19BG platforms. Gas is piped to the Bacton terminal via the Corvette and Leman A complex. It is named after the brigantine ship. Caravel 49/20 production is via the Brigantine to Corvette pipeline. Shamrock production is via Caravel 49/20

Sean

These consist of the Sean P (PD and PP) and the (smaller) Sean RD platforms. The Sean North field was discovered in May 1969 and Sean South was discovered in January 1970, and production started in October 1986. It is owned equally by Shell, Esso Exploration & Production UK Ltd, Union Texas and Britoil (BP) but run by Shell. Sean East was discovered in June 1983, with production starting in November 1994.[11]

Clipper

It is part of the Sole Pit field. It was discovered in March 1968. Production started in October 1990. It is owned by Shell and Esso and run by Shell. The Clipper complex has been developed as a nodal platform Clipper P (PW, PT, PM, PC, PR) for the Galleon, Barque, Skiff and Carrack Fields. It is named after the clipper type of ship

Barque

Barque PB and Barque PL are part of the Sole Pit complex. It was discovered in 1971. Production started in October 1990. It is owned by Shell and Esso and run by Shell. It is furthest north of the fields connected to Bacton, being further north of many of the Lincolnshire-connected gas fields. Piped to Bacton via Clipper complex. It is named after the barque design of ship.

Galleon

Galleon PG and Galleon PN are part of the Sole Pit complex. Production started in October 1994 and was discovered in September 1969. It is owned by Shell and Esso and run by Shell. Piped to Bacton via Clipper complex. It is named after the galleon type of ship.

Carrack

Carrack QA and Carrack West are located approx 120 km North East of Bacton Terminal. Production started in 2003. It is owned by Shell and Esso and run by Shell. Cutter QC exports gas via Carrack QA. Piped to Bacton via Clipper complex.

Shearwater

Run by Shell but owned by 28% by Shell UK Ltd, 28% by Esso Exploration & Production UK Ltd, 28% by ARCO British Ltd, 12% by Superior Oil (UK) Ltd, and 4% by Canadian Superior Oil UK Ltd. Discovered in September 1988 with production starting in September 2000. Connects to Bacton via the SEAL pipeline (Shearwater Elgin Area Line). The 474 km SEAL pipeline also connects to the Elgin-Franklin gas field.

Davy East

Production started in 2008. Connects to Bacton via the Indefatigable field.[12]

Tullow and Eni fields

Thames, Yare, Bure, Wensum and Deben

These fields are operated by Perenco, controlled from the Thames complex, formerly operated by Arco British Limited and then ExxonMobil. The field comprised the Thames 49/28A platform and the subsea installations all producing via Thames: Yare C 49/28, Gawain 49/29A, Bure O 49/28-8, Bure West 49/28-18 and Thurne 49/28 owned by Tullow/Eni. Cessation of all remaining production feeding to the Thames complex was declared in 2014 and decommissioning commenced.

Owned 43% by Tullow Exploration Ltd, 23% by AGIP (UK) Ltd, 23% by Superior Oil (UK) Ltd, and 10% by Centrica Resources Ltd. Production from all five fields began in October 1986. Thames was discovered in December 1973; Yare in May 1969; Bure in May 1983; and Wensum in October 1985. They are run by Tullow Oil as the Thames complex. Connects to the Tullow Bacton terminal via the Thames pipeline.[13] Bought from Agip (of Italy) by Tullow in 2003. The fields are named after the River Thames, the Yare, Bure, Wensum of Norfolk, and the Deben of Suffolk.

The Thames complex has one Solar Mars, and one Ruston Tornado and TB5 gas turbines for its compressor.

Welland NW & Welland S

Run initially by Arco, ExxonMobil and lastly Perenco and owned 34% by Tullow Exploration Ltd, 55% by Esso, and 11% by Consort EU Ltd. Welland NW was discovered in January 1984 and Welland S in June 1984. Production started in September 1990. Situated south-east of the Thames complex to which it connects to Bacton. Named after the River Welland. The Welland proved uneconomical by 2005 and was decommissioned and removed in 2010.

Hewett

The Hewett field has several reservoirs at relatively shallow depths: 3,000-4,200 ft (910-1280 m). The structure is a north-west to south-east anticline about 18 miles (29 km) long by three miles (4.8 km) wide.[6] It is Operated by Eni UK and comprises the complexes - Dawn, Big Dotty, and Deborah, and Delilah, Della and Little Dotty. It is owned 89.31% by Eni UK with Perenco owning the remaining 10.69%. It was discovered in October 1966 and production started in July 1969. It had initial recoverable reserves of 97 billion m3.[7] The Hewett field produced gas from four subsea reservoirs: Permian Rotliegendes sandstone, Permian Zechstein magnesian limestone, and Lower Triassic Lower Bunter shale and Upper Bunter sandstone. The Upper Bunter formation comprised sour (high sulphur) gas. This required the provision of sour gas treatment facilities at Bacton, before production from the Upper Bunter was suspended in 2000. Hewett has two 30-inch pipelines to Bacton (27.7 km and 32.8 km). It is the set of fields nearest to Bacton being 25 miles (40 km) east of Great Yarmouth. It was run by Phillips Petroleum, which became ConocoPhillips, and then largely owned and run by Tullow Oil before lastly being purchased by Eni UK.

Fizzy

Situated east of the Thames complex and is not yet a producing field.

Horne and Wren

South of, and producing to, the Thames complex. Production started in June 2005. Bought by Tullow from BP in 2004, then 50% sold to Centrica. Operated before 2004 by Shell.

Tristan

It is owned and operated by Perenco Gas UK Ltd. Discovered in May 1976 and production started in November 1992. It was connected to Bacton via the Welland and Thames platforms, the Welland platform having been removed in 2010, and situated east of the Thames complex. Named after Tristan of the Arthurian legend.

Wissey

South-west of the Thames complex, directly south of the Welland gas field. Named after the River Wissey in Norfolk.

Arthur

Situated between the Hewett (to the west) and Thames (to the east) complexes. Connects to Bacton via the Thames complex. Production started in January 2005. Formerly owned by Tullow and run by Esso. Named after King Arthur.

Perenco gas fields[14]

Leman

Block 49/27 of the Leman field is licensed to, and operated by, Perenco UK Ltd, originally by the Gas Council-Amoco. It was discovered in August 1966 and production started in August 1968. It had initial recoverable reserves of 292 billion m3. It comprises the following installations, platforms and complexes: Leman 49/27A (AD, AP, AC, AQ, AX); 49/27B (BD, BP, BT); 49/27C (CD, CP); 49/27D (DD, DP); 49/27E (ED, EP); 49/27F (FD, FP); 49/27G; 49/27H; and 49/27J. Gas is routed to Bacton via two 30-inch pipelines from Leman 49/27A and Leman 49/27B.

Indefatigable

Blocks 49/23 and 49/18 of the Indefatigable field are licensed to, and operated by, Perenco, originally by the Gas Council-Amoco. The field was discovered in June 1966 and production started in September 1971. It had initial recoverable reserves of 125 billion m3.[7] It comprises the following installations, platforms and complex: Indefatigable 49/23A (AT, AC, AQ); 49/23C (CD, CP); 49/23D (including the Baird field); 49/23E (Bessemer) and the subsea installation N.W.Bell (49/23-9); Inde 49/18A; and 49/18B. The decommissioned Shell Indefatigable field 49/24 formerly produced gas via the Inde 49/23A complex. Gas from Indefatigable 49/24AT is routed to Bacton via the Leman 49/27B complex.

Lancelot

The Lancelot complex (48/17A) is connected to Bacton via the LAPS pipeline (Lancelot Area Pipeline System), and it is also known as the LAPS complex. It is run by the Anglo-French Perenco.

Gawain

Gawain 49/29A is operated by Perenco UK Limited. It is owned by Perenco Gas UK Ltd 50% and Tullow Oil Ltd 50%. Discovered in December 1988 with production starting in October 1995. It connects to Bacton via the Thames complex. Situated north-east of the Thames field, completely separate (to the east) of the other Arthurian-named fields.

Galahad & Mordred

Galahad & Mordred 48/12BA are operated by Perenco UK Limited. It is owned 72.23% by Perenco Gas UK Ltd, 15% by Chieftain Exploration UK Ltd, 10% by Premier Pict Petroleum Ltd, and 3% by Chieftain International North Sea Ltd. Discovered in December 1975 and production started in November 1995. Connects to the Eni plant at Bacton via the Lancelot platform.

Guinevere

Guinevere 48/17B is operated by Perenco UK Limited. It is owned 49.5% by Perenco Gas UK Ltd, 25.5% Perenco UK Limited and 25% Nobel Energy Inc. Discovered in May 1988 and production started in June 1993. Connects to the Eni plant at Bacton via the Lancelot platform. Situated west of the (central) Lancelot field.

Camelot N and Camelot C & S

Run by Petrofac, and owned by ERT. Camelot N discovered in November 1967 and Camelot C & S discovered in June 1987. Production started in October 1989. Connects to Bacton via the Leman complex.

Excalibur

Excaliber EA 48/17A is owned and operated by Perenco, production is via Lancelot 48/17A. The northern-most Arthurian gas field in the Lancelot complex.

Trent

It is owned by Perenco UK Ltd. It was previously owned and operated by ARCO (Atlantic Richfield Company), and is now run by Perenco. It was discovered in March 1991 and production started in November 1996. It connects to the Perenco Bacton terminal via the Eagles pipeline. Has two Solar Mars gas turbines for the compressor.

Orwell

It is owned by Tullow Oil Ltd. It was run by ARCO, and is now run by Perenco. It was discovered in February 1990 with production starting in August 1993. East of the Thames complex, to which it connects, and furthest east of the Bacton gas fields. Bought by Tullow from ChevronTexaco (ChevTex, since May 2005 known as Chevron) in 2004. Named after the River Orwell in Suffolk.

Tyne South & Tyne North

Furthest north of the Bacton gas fields, around the same latitude north as Teesside. Owned by Perenco UK Limited. It was run by ARCO, and is now operated by Perenco. Discovered in January 1992 and November 1996. Connects to Bacton via the Interfield pipeline and Eagles pipeline.

Baird and Deborah gas storage

The Rough facility is currently the only depleted UK offshore gas field reservoir that is used for gas storage and retrieval. Several projects have been developed to use other depleted gas fields but none have proved to be economically viable. Two examples associated with Bacton are the Baird and the Deborah Gas Storage Projects.

Baird gas storage project

Perenco’s Baird field is located in Block 49/23, 86 km off the coast of Norfolk. It is located adjacent to Perenco’s Indefatigable field through which it exports gas via Inde 49/23D.

The Baird gas storage project was to have been built by Centrica Storage and Perenco (UK) Ltd. Centrica acquired 70% interest in the project from Perenco in February 2009. The companies formed a 70/30% joint venture called Bacton Storage Company to operate the facility when completed.[15]

The project involved the transport of gas from the National Transmission System (NTS) through the Perenco onshore terminal at Bacton and then by pipeline offshore to be injected and stored in the Baird reservoir. Gas injection would take place during the Summer and be reversed during the Winter drawing gas from the reservoir for processing at Bacton and delivery into the NTS.

The onshore facilities included three gas turbine driven compressors, a gas dehydration plant, reception heaters, a mono ethylene glycol (MEG) storage and regeneration plant, additional gas fiscal metering systems and a vent stack. These facilities would be built on Perenco’s terminal at Bacton. Planning permission was given by North Norfolk District Council on 27 July 2010.

The offshore facilities were a single four-legged normally unattended installation (NUI). The installation would have 18 well slots with up to 14 development wells. The NUI would be connected to Bacton through a 100 km long 38-inch diameter bidirectional pipeline. A 4.5-inch MEG line was to run in parallel delivering MEG from Bacton to the NUI.

The field would have a storage capacity of 81 billion cubic feet (2.3 billion cubic metres) making it the second largest gas storage facility in the UK. The facility would have a 50 year design life.

The project was expected to be completed in 2013 but was put on hold in 2012 with no construction work taking place. On 23 September 2013 Centrica announced[16] that they would not proceed with the Baird project in light of weak economics for gas storage projects and the announcement by the Government on 4 September 2013 ruling out intervention in the market to encourage additional gas storage capacity in the UK.

Deborah gas storage project

Eni’s Deborah field lies in Blocks 48/28, 48/29, 48/30 and 52/03 about 40 km from the Norfolk coast. It is adjacent to the Hewett field through which it has produced gas since 1970.

The project was developed by Eni Hewett Limited. As with the Baird project gas would have been injected into the offshore reservoir during Summer months and withdrawn during the Winter and treated onshore at Bacton for delivery into the NTS.[17]

The onshore facilities would include new reception facilities for the pipelines, two compressor houses for four new compressor, water treatment works, glycol storage and two vent stacks. Planning permission for the onshore facilities was given by North Norfolk District Council on 24 November 2010.

The offshore facilities would be two NUI platforms about 2 km apart located above the Deborah reservoir. There would be a total of 33 injection/withdrawal wells plus two monitoring wells spread between the two platforms. Each platform would be connected to Bacton by one of two 41 km long 32-inch diameter bidirectional pipelines. A 2 km long 32-inch pipeline would connect the two platforms. A 41 km glycol pipeline would be piggybacked to one of the gas lines. A 41 km power and fibre optic control monitoring and communication cable from Bacton to one of the platforms and 2 km cables between the platforms would be provided.

The Deborah field was to have a storage capacity of 4.6 billion cubic metres. The facility was to have a 40-year design life. A gas storage licence was granted by the Department of Energy and Climate Change (DECC) on 22 October 2010.[18] Start up was planned for April 2015. The project was mothballed in Autumn 2013.

Installation identification

An offshore installation on the UK Continental Shelf may comprise a single integrated platform or two or more bridge-linked platforms. Installations are identified by a large black-on-yellow sign on the installation. This may give the name of the original or current owner or operator, the field name, and a set of numbers and letters, e.g. Shell/Esso Leman 49/26A. The numbers identify the Quadrant and Block where the installation is located, e.g. 49/26 is in Quadrant 49 Block 26.[6] The first letter is a sequential letter (A, B, C, D, etc) identifying each installation within a field. The second and subsequent letters may designate a platform's function, e.g. the Leman 49/26A complex comprises four bridge-linked platforms 49/26AP (Production), 49/26AD1 (Drilling 1), 49/26AD2 (Drilling 2), and 49/26AK (Compression). Common designations are:

| Letter(s) | Platfom function |

|---|---|

| A | Accommodation |

| C | Compression |

| D | Drilling (see note) |

| FTP | Field Terminal Platform |

| H | Hotel accommodation |

| K | Compression |

| M | Manifold, Main |

| P | Production, Processing |

| Q | Living Quarters |

| R | Riser, Reception |

| T | Terminal |

| X | Miscellaneous, e.g. as Low pressure compression, Reception. |

Note: Drilling refers to the original function of the platform to support well drilling operations. No Southern North Sea installation has permanent drilling facilities.

On some installations the letters simply provide a unique two letter identity, e.g.Tethys TN, Viscount VO.

Accidents and incidents

On 13 August 1981, 11 gas workers lost their lives in the G-ASWI North Sea ditching, in a Wessex helicopter. At 6pm on 28 February 2008, there was an explosion and fire at the Shell UK terminal, for which Shell were fined £1 million.[19]

See also

- National Transmission System

- Easington Gas Terminal

- St Fergus Gas Terminal

- Rampside Gas Terminal

- Theddlethorpe Gas Terminal

- CATS Gas Terminal

References

- ↑ Cassidy, Richard (1979). Gas: Natural Energy. London: Frederick Muller Limited. p. 52.

- 1 2 3 4 5 Wilson, D. Scott (1974). North Sea Heritage: the story of Britain's natural gas. British Gas. pp. 27–30.

- ↑ Hewett Bacton Terminal Archived September 22, 2010, at the Wayback Machine.

- ↑ Cassidy, Richard (1979). Gas: Natural Energy. London: Frederick Muller Limited. p. 39.

- ↑ "BBL Company".

- 1 2 3 Tiratsoo, E.N. (1972). Natural Gas. Beaconsfield: Scientific Press Ltd. p. 209.

- 1 2 3 4 Cassidy, Richard (1979). Gas: Natural Energy. London: Frederick Muller Limited. p. 54.

- ↑ "Shell Indefatigable decommissioning" (PDF).

- ↑ Shell Indefatigable Archived January 6, 2011, at the Wayback Machine.

- ↑ Shell Leman Archived January 6, 2011, at the Wayback Machine.

- ↑ Shell Sean Archived January 6, 2011, at the Wayback Machine.

- ↑ Perenco fields

- ↑ Tullow - Thames

- ↑ "Map of Perenco Southern North Sea infrastrucure" (PDF).

- ↑ "Hydrocarbons Technology Baird Project".

- ↑ "Centrica's decision on Baird".

- ↑ "Eni Deborah Gas Storage".

- ↑ "DECC Licence for Deborah".

- ↑ Shell fined £1m plus £240,000 costs

External links

- Tullow Oil

- Interconnector(UK) Ltd

- Perenco gas fields in the North Sea

- Dismantling of Eni terminal

- BBL Company

News items

- Emergency procedures in January 2011

- Protestors arrested in April 2008

- Police protection in January 2007

- Interconnector starts in December 2006

- Arthur field starts in January 2005

- New company BBL formed in July 2004

- Carrack field in February 2003

- Helicopter crash in July 2002